Understanding Machinery Hazards

Before discussing safety practices, it’s crucial to recognise the common hazards associated with machinery:

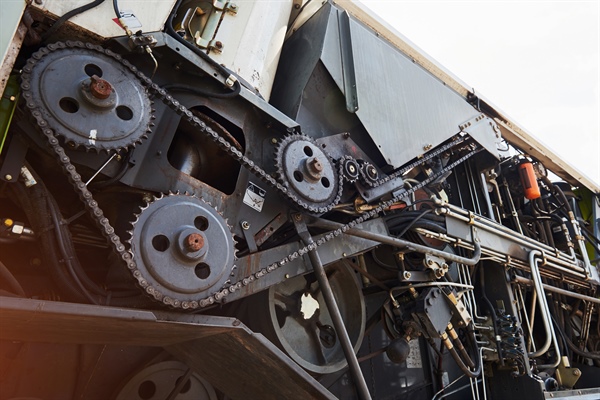

- Mechanical Hazards: Moving parts, rotating equipment, sharp edges, and pinch points.

- Electrical Hazards: Faulty wiring, inadequate earthing, or exposed live parts.

- Operational Hazards: Errors during use, lack of training, or unauthorised modifications.

- Environmental Hazards: Poor lighting, slippery floors, or obstructed workspaces.

The Importance of Safe Machinery Use

Unsafe machinery operation can lead to:

- Injuries: Cuts, burns, fractures, or amputations.

- Fatalities: Serious incidents resulting from entanglement or crushing.

- Downtime: Equipment damage and production delays.

- Legal Consequences: Fines or penalties for non-compliance with safety regulations.

Key Principles for Safe Machinery Use

1. Conduct Risk Assessments

A thorough risk assessment should:

- Identify potential hazards associated with each piece of machinery.

- Evaluate the likelihood and severity of accidents.

- Develop control measures to mitigate risks.

2. Implement Safeguarding Measures

Effective safeguarding minimises exposure to hazardous parts and prevents accidents:

- Guards: Install fixed, interlocked, or adjustable guards to shield workers from moving parts.

- Safety Devices: Use emergency stop buttons, light curtains, or pressure-sensitive mats to halt machinery during emergencies.

- Barriers: Erect physical barriers to keep unauthorised personnel away from machinery.

3. Provide Adequate Training

Operators must be trained to:

- Understand the machine’s operation, capabilities, and limitations.

- Recognise hazards and follow safe work procedures.

- Conduct routine inspections and report defects.

- Use personal protective equipment (PPE) appropriately.

4. Follow Proper Lockout/Tagout (LOTO) Procedures

LOTO procedures are critical during maintenance or repair:

- Lockout: Isolate energy sources and secure machinery with locks to prevent accidental start-up.

- Tagout: Attach tags to indicate that the equipment is out of service.

- Always verify that energy sources are fully deactivated before commencing work.

5. Maintain a Clean and Organised Workspace

- Keep floors dry and free of debris to prevent slips and trips.

- Ensure tools and materials are stored securely and not obstructing walkways.

- Maintain proper lighting around machinery for better visibility.

6. Regular Maintenance and Inspections

Preventive maintenance ensures machinery operates safely and efficiently:

- Follow manufacturer’s guidelines for servicing intervals.

- Inspect components such as belts, gears, and electrical systems regularly.

- Replace worn or damaged parts immediately to avoid malfunctions.

7. Use Personal Protective Equipment (PPE)

Depending on the machinery and tasks involved, workers may need:

- Safety glasses or goggles.

- Ear protection for noisy environments.

- Gloves resistant to cuts or chemicals.

- Steel-toed boots for foot protection.

Emergency Preparedness

Despite precautions, emergencies can still occur. Be prepared by:

- Establishing and practicing emergency response plans.

- Ensuring easy access to first aid kits and fire extinguishers.

- Training workers to respond to incidents, such as shutting down machinery or assisting injured colleagues.

Legal and Regulatory Compliance

Adherence to workplace safety regulations is non-negotiable. Depending on your location, you may need to follow guidelines such as:

- PUWER (Provision and Use of Work Equipment Regulations 1998) in the UK.

- OSHA (Occupational Safety and Health Administration) Standards in the US.

- These regulations mandate proper training, risk assessments, and maintenance protocols for machinery.

Promoting a Safety Culture

A safe workplace starts with a safety-first mindset:

- Encourage employees to report hazards or unsafe practices without fear of blame or ridicule.

- Conduct regular safety audits and meetings to reinforce best practices.

- Recognise and reward adherence to safety protocols.

Conclusion

The safe use of machinery is a shared responsibility that requires vigilance, training, and adherence to established protocols. By implementing robust safety measures and fostering a culture of accountability, employers can minimise risks and create a secure working environment.

Remember, prevention is the best cure. Prioritise safety to protect your workforce and maintain operational excellence.

TTFN!